B Futura

High performance in modern design

Digital Virtual Assistant

Digital Virtual Assistant, questo l’acronimo di Di.V.A. Il primo sistema di controllo e tracciabilità dei dispositivi di sterilizzazione MOCOM su Cloud. I dati, una volta salvati, saranno a disposizione degli operatori accedendo alla pagina web dedicata. Con Di.V.A è possibile:

- Accedere a video tutorial

- Visualizzare i cicli effettuati

- Controllare l’efficienza e lo stato della macchina

- Consultare le statistiche di utilizzo della macchina

- Monitorare la frequenza dei test di sterilizzazione

Born to simplify your life, reduce costs, and ensure superior efficiency. Equipped with advanced connectivity and traceability systems, the Futura autoclave further raises the bar in the world of sterilization.

- 17l

- 22l

- 28l

The first one capable of using tap water

Incorporated filtration in a stand-alone machine

The incorporated system makes it possible to increase the surgery efficiency, eliminating demineralised water management issues. Recipients’ storage and deterioration of machine internal components caused by poor water quality will be a thing of the past.

Operating principle

Unlike traditional sterilizers, Futura does not require any external water connection for mains water treatment. Thanks to the demineralisation filter on the main tank, the user can fill the latter with plain tap water, thereby significantly optimising spaces, streamlining processes and achieving considerable savings. Futura’s filtration system guarantees unprecedented ease of operation.

Operating principle

Ease of use

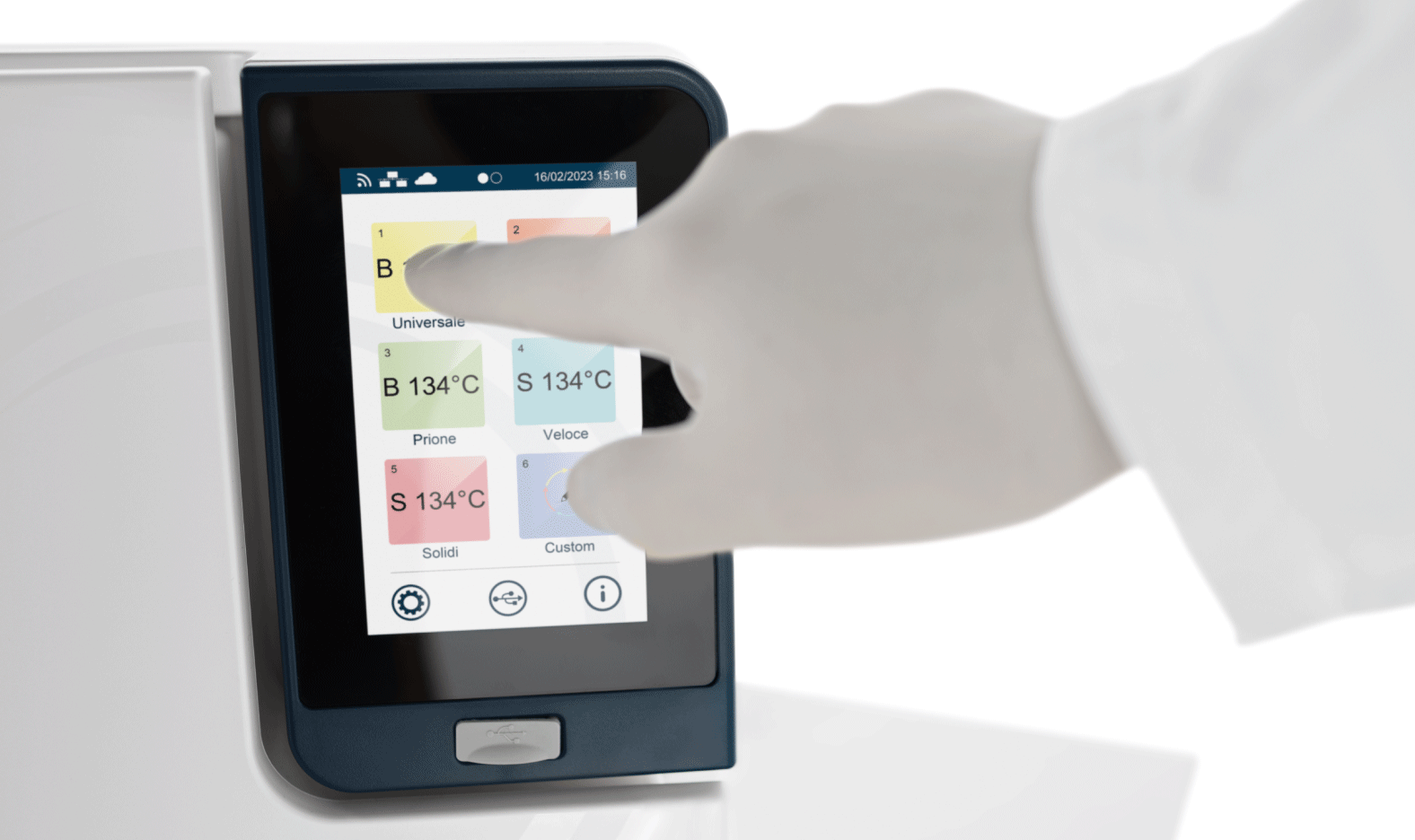

5” color touch display for a simple and intuitive interface

B Futura is the intelligent dental sterilizer that ensures excellent performance, also thanks to the capacitive color touchscreen loaded with a simple and intuitive user interface. Video tutorials and light indicators are innovative tools that assist the operator in daily activities.

Shared printer

The optional printer allows the sterilization process performed with the autoclave to be finalized.

For optimized management, the printer can be shared among multiple enabled sterilizers connected to the same network. A single printing station, fast and reliable.

Thanks to the printer, it is possible to create adhesive labels with QR codes or barcodes to be applied to sterile packages at the end of each cycle.

Shared printer

A complete B cycle in 31 minutes

Reliable and high-performance internal components reduce sterilization cycle times. The exclusive Modular Drying function also allows the operator to select the amount of material to be sterilized, adjusting the drying duration and thus reducing the overall cycle time.

A complete B cycle in 31 minutes

Sterilconnect

Any network-connected mobiledevice - tablet or smartphone - can be usedto interact with the autoclave, simplifyingdaily management of the sterilizationprocess. A simple yet complete graphicinterface lets you monitor device status andmanage the various sterilizer functions

Sterilconnect

.jpg)

Advanced connectivity

Incorporated WiFi for remote support and optional cloud

At the end of each sterilization cycle, the machine stores a report inside its memory. The user can download the cycles in PDF format at any time through the front USB port or automatically store them in the cloud using the WiFi and Di.V.A. system.

Customisable cycle

CUSTOMISED CYCLE

Cycle parameters can be set to meet specific user requirements in complete safety, by choosing from a wide range of standard-compliant values.

OPERATOR ID

Authorises access to the autoclave. By entering a PIN code, a record can be kept of the machine cycle history to ensure monitoring of disinfection and sterilisation processes.

Start and drying

DELAYED START

The delayed start option lets users program delayed cycle start times, allowing rationalised use of the dental equipment.

EXTRA DRYING

Function that lets users set customised drying times for particularly challenging loads.

Traceability software

MyTrace is Cefla’s traceability software available for Futura. By using this programme, each set of sterilized instruments can be associated to the patient through a bar code. This essential software completes the sterilization process and provides legal protection to dentists.

Remote support with Easy Check

All sterilizers of the Futura range are equipped with incorporated WiFi and Ethernet port. Connected to the Internet by enabling the Easy Check service, they can receive remote support. Intervention times can be significantly reduced thereby allowing technicians to keep machines constantly efficient.

Di.V.A (Digital Virtual Assistant)

It is the first cloud-based control and traceability system for MOCOM sterilization devices.

All Accessories

Shared printer

The optional printer, through the generation of labels or reports, allows the finalisation of the sterilisation process, providing the user with the basis for a correct traceability. For optimised management, the printer can be shared between several network-enabled sterilisers. A single, fast and reliable printing workstation rationalises the use of space, resulting in significant savings.

Front filling kit

Allows the operator to fill the main tank frontally through a quick coupling.

Automatic filling kit

Consists of an external pump powered by the sterilizer and allows demineralised water to be withdrawn from a tank or recipient.

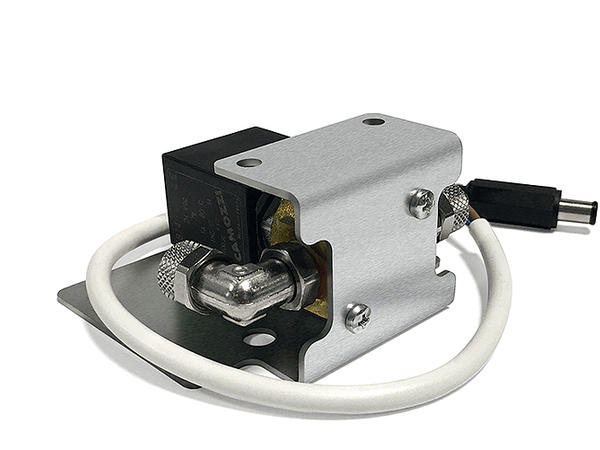

SV aux kit

This kit allows the sterilizer to be interfaced with surgery demineralising systems so the sterilizer only draws water from the system as and when necessary.

Modular tray holder

Modular housing system for filling the sterilizer. Provided with 3 pairs of tray-housing shelves, it allows for the full use of the chamber diameter and the introduction of even cumbersome loads.

Bar code reader

The bar code reader, usable on the most common PCs, makes it possible to complete the traceability process and associate bar code labels to patients.

Related product

Supreme

-1.png)

.jpg)